Explain 3D Printing ?

Introduction

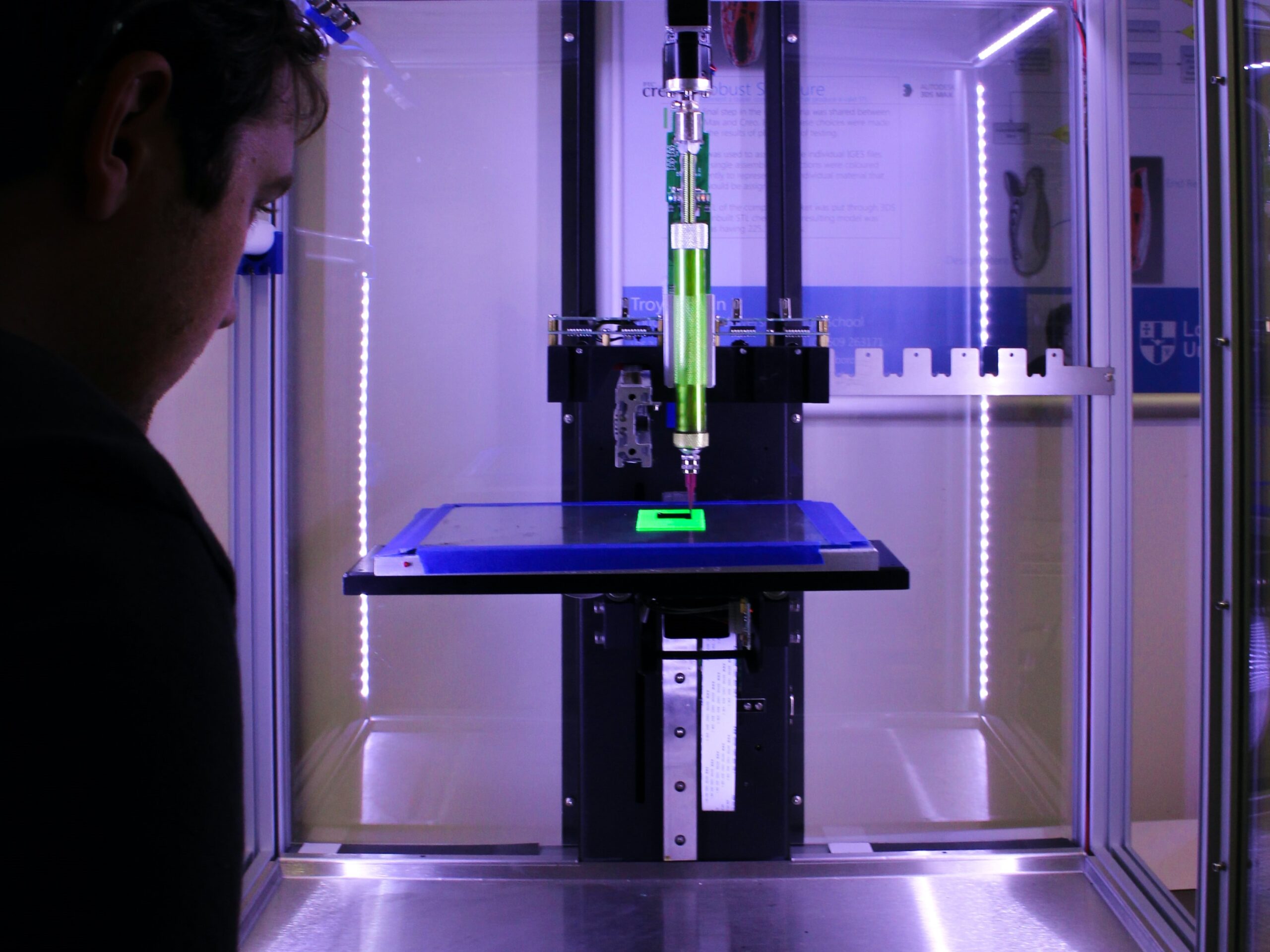

3D printing is a revolutionary technology that transforms virtual visions into tangible objects. It involves creating 3D objects layer by layer, guided by computer-designed models. This method allows for the use of polymers, metals, and biological materials, transforming manufacturing from toys to medical devices. 3D printing not only transforms virtual concepts into physical items but also allows for creativity and implementation of ideas.

History of 3D Printing

- Originated in the 1980s with the invention of stereolithography by Chuck Hull.

- Stereolithography was the first commercially feasible 3D printing method using ultraviolet light.

- Advancements led to the emergence of Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS).

- 3D printing has evolved from rapid prototyping to a versatile tool used across industries.

How 3D Printing Works.?

A. Basic Principles

3D printing is a process that builds the final product layer by layer, using additive manufacturing principles. This involves creating a digital model using CAD software, which is then divided into thin layers to guide the 3D printer during the manufacturing process. This method differs from traditional subtracting material methods.

B. Materials Used

3D printing is versatile due to its large range of materials, which includes polymers, metals, ceramics, and biological substances. The material used is determined by the intended usage, with distinctive features such as flexibility, strength, or bio-compatibility allowing it to cater to a wide range of industries and applications.

C. Printing Process

3D printing involves layer-by-layer deposition of materials by a 3D printer, which interprets the digital model and moves accordingly, adding layers until the complete object is formed. The deposition method varies depending on the 3D printing technology used, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), or Selective Laser Sintering (SLS), each with its unique application and solidification method for the desired 3D printed outcome.

Applications of 3D Printing

- Prototyping: During the design phase, 3D printing makes physical models of products, allowing for speedy and cost-effective testing and refining.

- Healthcare: 3D printing is utilized to create patient-specific implants, prosthetics, and personalized medications, which aid in surgery planning and patient outcomes.

- Aerospace: 3D printing is used in the aerospace industry to produce lightweight components and sophisticated pieces, increasing efficiency and reducing fuel consumption.

- Automotive: 3D printing is essential for prototyping, customizing parts, and manufacturing end-of-life components, lowering development time and costs.

- Consumer Goods: 3D printing is used to create personalized accessories and detailed art works, providing consumers with a level of individuality and creativity that traditional manufacturing processes cannot provide.

Advantages of 3D Printing

- Customization: 3D printing allows for the creation of unique, individualized items for various industries.

- Rapid Prototyping: 3D printing accelerates the product development cycle by converting digital concepts into physical prototypes.

- Cost-Efficiency: Traditional manufacturing processes often require expensive molds and tooling, making 3D printing economically viable for low-volume production and custom projects.

- Reduced Material Waste: 3D printing is an additive process, creating objects layer by layer, minimizing material waste and contributing to cost savings.

Challenges and Limitations

Speed:

- 3D printing’s speed is a significant challenge, especially for mass production industries.

- Traditional manufacturing methods may have an advantage in terms of speed.

Material Limitations:

- The variety of materials for 3D printing has expanded, but not all are suitable for every printing method.

- Achieving specific material properties like strength or flexibility can be challenging.

Post-Processing Requirements:

- Post-processing steps are often necessary to achieve the desired finish.

- These steps can increase the time and labor required, impacting perceived efficiency.

Future Trends in 3D Printing

- Advancements in Materials: Researchers and industry specialists are investigating novel materials with improved properties. Biocompatible materials are opening the way for new medical uses.

- Integration with Artificial Intelligence: AI algorithms can optimize designs for improved structural integrity and performance. AI-powered process monitoring can improve 3D-printed object quality control.

- Sustainability initiatives: As environmental issues gain prominence, 3D printing sustainability efforts are gaining traction. Researchers are investigating environmentally friendly materials, and the business is shifting toward more sustainable practices.

3D Printing in Everyday Life

Impact on Home Use

- 3D printing is increasingly used in everyday life, transforming homes into manufacturing hubs.

- Users can create personalized items like domestic appliances and decorative pieces.

- As 3D printers become more user-friendly and affordable, their adoption in homes is expected to rise.

Do-It-Yourself (DIY) Projects

- Allows Do-It-Yourself (DIY) enthusiasts and hobbyists to realize their creative ideas.

- Allows for the creation of complex, unique objects at home.

- Allows for the creation of one-of-a-kind home decor and the creation of custom parts.

- Promotes an environment of creativity and self-expression.

Educational Applications

- Provides opportunities for hands-on learning.

- Converts abstract ideas into concrete objects.

- Improves understanding of a variety of subjects.

- Allows for more engaging and dynamic lessons.

- It improves the educational path from geometric shapes to historical items.

- Prepares students for future careers in digital design and manufacturing.

3D Printing and the Environment

3d printing with sustainable practices

- The additive process of 3D printing reduces material waste, which aligns with sustainability aims.

- The versatility of 3D printing enables the investigation of sustainable and bio-based possibilities.

Recycling in 3d printing

- Reprocessing unused or abandoned materials conserves resources.

- Filament recycling system innovations enable a closed-loop approach to material consumption.

- This decreases 3D printing’s environmental impact and conforms with circular economy concepts.

Educational Resources for 3D Printing Enthusiasts

Online Courses:

- Enthusiasts can do courses on 3D printing from Coursera, Udemy, and LinkedIn Learning.

- It cover design principles, software proficiency, and practical applications.

- It enable self-paced learning from home.

Seminars and workshops:

- Provide opportunities for hands-on learning.

- Local makerspaces, community colleges, and industry events organize the event.

- Industry professionals present seminars on new trends, creative applications, and best practices.

How to Get Started with 3D Printing

3D Printing Beginners Guide

- When selecting a printer, keep your budget, intended purpose, and technical requirements in mind.

- Conduct model research, read user evaluations, and evaluate build volume and print resolution.

Learning Basic CAD Skills

- Learn the fundamentals of Computer-Aided Design (CAD).

- Use free software such as Tinker CAD or more complex options like as Fusion 360 or Blender.

- Begin with simple designs and work your way up to more complex ones.

Troubleshooting Common Issues

- Get familiar with frequent concerns such as layer adhesion challenges, nozzle blockages, and warping.

- For troubleshooting, consult online forums, community organizations, and manufacturer support options.

- Learn about printer maintenance, calibration, and filament selection to have a more enjoyable 3D printing experience.

Conclusion

The world of 3D printing has altered many sectors of our existence, including prototypes, healthcare, aerospace, and many more. Its adaptability extends to home use, DIY projects, and educational applications. Speed, material limits, and post-processing requirements are among the challenges. However, online courses and workshops provide chances for ongoing learning.

The future of 3D printing seems bright, thanks to breakthroughs in materials, AI integration, and sustainability. As technology becomes more widely available, its influence on home use and DIY projects will grow, boosting creativity and individual expression.